| Name of Invention:

Air-Driven Electric Power Generator Air Generator Patent Application 10-136063 Utility Application #10/136063 Inventors Name and Address

Version With Markings To Show Changes Made Cross-Reference to Related Applications

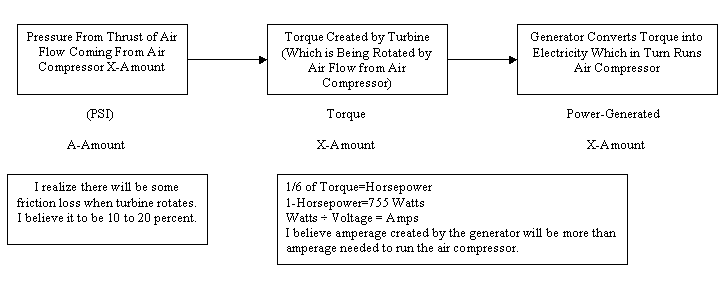

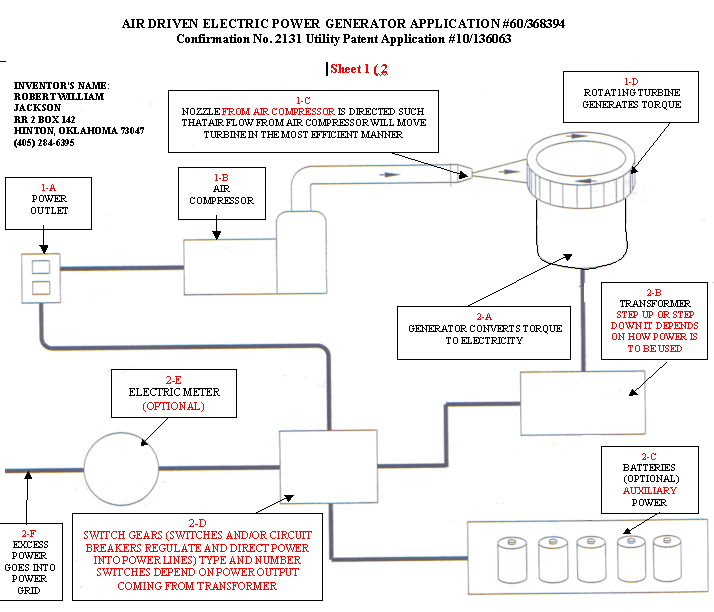

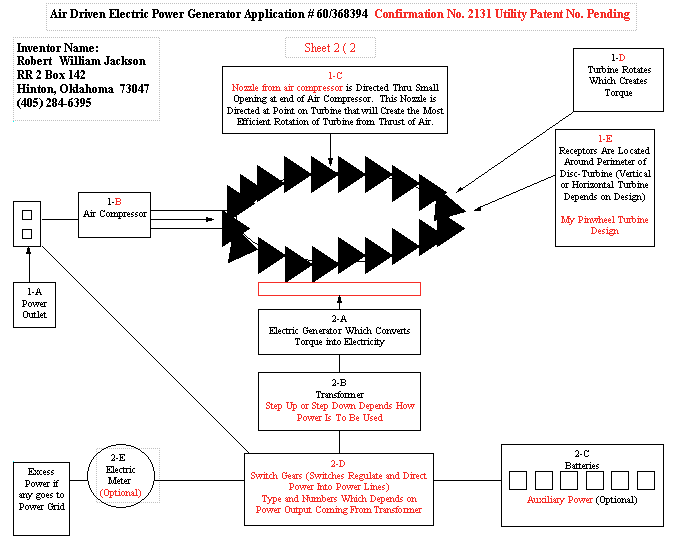

This theory was developed by Robert William Jackson. I claim to be the original inventor of this concept. This is a renewable energy device using basic air-flow principals. My idea is to use an air compressor (See 1-B, Sheet 1 and 2) with a high pressure nozzle (See 1-C, Sheet 1 and 2). The nozzle is then directed into a turbine (See 1-D, Sheet 1 and 2). The theory is to rotate the turbine which in turn is connected to an electric generator (See 2-A, Sheet 1 and 2). The theory is to rotate turbine with air-flow from nozzle which is connected to air-compressor. The pressure from air-flow which comes from end of nozzle should be direct at point of the turbine which creates the most efficient rotation of turbine (See 1-C, Sheet 1 and 2). This rotation of turbine creates torque (See 1-D, Sheet 1 and 2) in which generator converts into electricity (See 2-A, Sheet 1 and 2). Brief Summary of the Invention I claim you can create more electricity than what it takes to run the air-compressor. The device creates more power than what it takes to power the device. Detailed Description of Invention 0001 The power used to run the air-compressor (See 1-A, Sheet 1 and 2) depends on the type of air-compressor that is used. 0002 The nozzle from the air-compressor should have a small opening at the end (which creates more air pressure). The diameter of this opening should be the width which creates the most pounds per square inch pressure this particular air compressor can produce. The end of the nozzle is directed at the point on a turbine that will create the most efficient rotation of the turbine from the thrust of the air-flow (See 1-C, Sheet 1 and 2). 0003 I claim the higher the pounds per square inch (PSI) rating of the air-compressor directly increases the power potential of the device. The compressor, generator and the design of the turbine all need to be in the right ratio. This means the generator and turbine need to be capable of generating more power than what it takes to run air-compressor. At the same time the air compressor needs to be capable of producing enough force to generate this amount of electricity. The nozzle and turbine need to be in proper alignment for the most efficient operation of this device (See 1-C, Sheet 1 and 2). This deals with the maximum rotation of turbine (See 1-D, Sheet 1 and 2) due to the PSI pressure coming from end of the nozzle which is connected to the air compressor. You can adjust power output by the pressure (PSI) coming thru the nozzle. 0004 The electricity that the generator creates is directed into a transformer which decreases or increases the voltage (See 2-B, Sheet 1 and 2). Either way electricity that comes from transformer is directed into some kind of switch gear device (See 2-D, Sheet 1 and 2). This device regulates and directs the electric power. Electric meter or some sort could be used to measure the amount of electricity that comes from switch gear device (See 2-E, Sheet 1and 2). This excess power goes into the power grid through power line (See 2-F, Sheet 1 and 2). 0005 This unit does require initial start-up. There are a lot of ways of doing this from batteries (See 2-C, Sheet 1 and 2) gasoline generators or from any standard power source (See 1-A, Sheet 1 and 2). 0006 The turbine design is very important. Here are few existing designs of turbines that would work with this concept. These turbines were designed for hydroelectric systems but could be adapted for this concept. I claim the Pelton, Harris, Banki, Nautilus and Neptune turbines would work with this concept. I like my own Pinwheel turbine design (See 1-E, Sheet 2). This design is patterned after the Pinwheel firework. My design is a solid disk. This disc should have at least 12 receptor cones positioned around the perimeter of the disc (dimensions are patterned after the Pinwheel firework). These receptors should be spaced evenly. I also believe that the receptors should point slightly outward from the disc for maximum retention of thrust from air-flow from the nozzle of the air-compressor. The size of the disc turbine shouldn’t be much larger in diameter than the width of the generator on which it is connected (just not too big or too small for maximum efficiency of rotation of the turbine in which torque is created. 0007 The blades or receptors of the turbine need to be spaced in such a way that they catch the full thrust of the air-flow coming from the end of the nozzle. 0008 My Pinwheel design has the receptor cones spaced close together around perimeter of the disc turbine. The round openings of the cone receptors receive the full force of the air-flow coming from the end of nozzle. 0009 With certain turbines you can line-up a second turbine to receive excess air-flow that receptors or blades on first turbine didn’t capture. Second turbine will rotate a lot less but still be able to contribute to power output. 00010 The turbine needs to be directly connected to the armature of the generator or the turbine needs to be connected to a spindle or rotor which is in turn is connected to the armature. It is important that armature rotates at same rate as turbine (Standard Generator Design). 00011 The nozzle needs to be in a fixed position. This position needs to be at the precise point where thrust from air-flow creates the most efficient rotation of turbine. The air-compressor also needs to be in a secure position. The generator also needs to be in a secured position. 00012 This device needs to be in a protected area with adequate ventilation

(air supply). This area needs to be water and wind proof. Extreme

heat or cold should be avoided for optimum performance of device.

Claims 1. I claim this concept to be a highly efficient way of producing electric

power.

Sequence Listing for Air-Driven Electric Generator

|