| Name of Invention:

Self-Powered-Hydro-Electric-Power Generator Hydro Patent Application Utility Patent No. 10-136521 Inventors Name and Address:

Version with markings to show changes made. Cross-Reference to Related Applications

Background of the Invention (Classification Definitions)

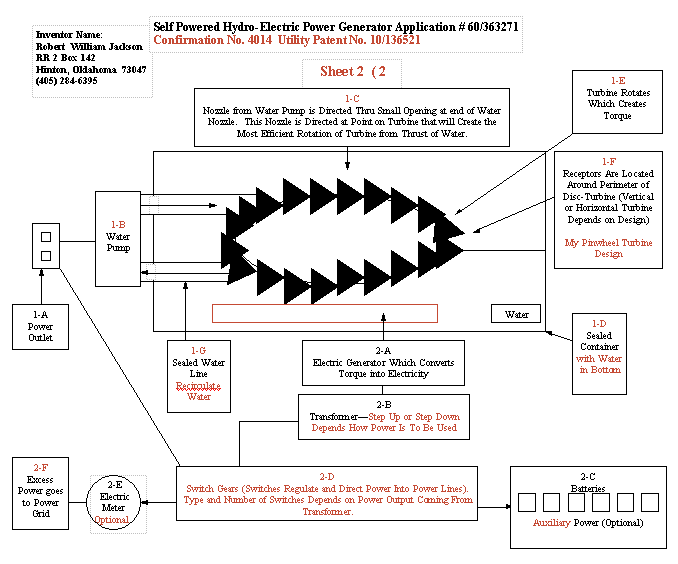

Brief Summary of the Invention My theory is you can generate more electricity from the hydro-electric generator than what it takes to run the water-pump which powers the generator. This invention is intended to produce electric power more efficiently than other methods in use at this time. I recommend the water to be recirculated even though this is not necessary to the power output potential of the device. Detailed Description of the Invention 0001 “This is a description of a concept. I’m using one-water pump. (See 1-B, Sheet 1 and 2) Power used to run the water pump depends on the type of water pump that is used (See 1-A, Sheet 1 and 2). The water pump also needs to be able to pump its own water (See 1-F, Sheet 1 and 1-G, Sheet 2) from a reservoir of water that is located at the bottom of a sealed and watertight container (See 1-D, Sheet 1 and 2). A rectangular shape for the container is recommended. The container needs to be large enough to hold adequate amount of water to keep water-pump operating at full potential. The water level needs to be maintained at this level due to evaporation. I recommend water temperature between 40° to 90° for optimum performance. The height of the container needs to be high enough so turbine is above the water line (See 1-F, Sheet 1). Also the container needs to be long enough so that the turbine is not too close to the back of the container. This prevents any back splash of water that might impede the rotation of the turbine. This also leaves room for a second turbine which can be lined up to capture excess thrust from water that first turbine didn’t capture. I call this excess water “tailwater.” This concept uses impulse turbines even though reaction type turbines (submerged turbines) could be used with this concept as long as power generated is more than power used to run water pump. This concept can be used anywhere as long as adequate amounts of water is available to run device. 0002 Nozzle from the water pump is inserted into the container (See 1-C, Sheet 1 and 2). The nozzle has a small opening. It should be the width which produces the highest PSI (Pounds Per Square Inch Pressure) rating the water pump can produce. The end of the nozzle is directed at the point on the turbine that will create the most efficient rotation of the turbine from the thrust of the water (See 1-C, Sheet 1 and 2). 0003 The electric generator can either be in or out of the container.

If the generator is in the container, it needs to be waterproof (See

2-A, Sheet 1 and 2). If the electric generator is located

outside of the container, the container needs to be watertight. This

means that the opening in the container that the spindle from the generator

is inserted into is watertight. The turbine inside the container

is connected to the spindle. The spindle is either part of the armature

or is directly connected to the armature of the generator. A round

ring of ball bearings should be located in this opening with the spindle

or armature inserted through this ring. This would also help stabilize

the electric generator which is essential to the operation of this device.

The water pump and the nozzle also need to be in a fixed position.

The water pump also could be located inside the container as long as the

water pump is waterproof. I think the life of the water-pump and

0004 I believe the higher the pounds per square inch (PSI) rating of the water-pump directly increases the power potential of the device. The pump, generator and design of the turbine all need to be in the proper ratio. This means the generator and turbine need to be capable of generating more power than what it takes to run water-pump at the same time the water-pump needs to be capable of producing enough force to generate this amount of electricity and the ability to pump this amount of water for an extended amount of time. The nozzle and turbine needs to be in proper alignment for the most efficient operation of this device (See 1-C, Sheet 1 and 2). This deals with the maximum rotation of turbine due to the PSI pressure of the water coming from the pump (See 1-C, Sheet 1 and 2). This creates torque which the generator converts into electricity (See 2-A, Sheet 1 and 2). I envision a water-pump which you can adjust the water pressure (PSI). This would enable you to adjust the power output of the device. The power it takes to run-water pump would decrease or increase accordingly to the water pressure (PSI). 0005 The turbine needs to be directly connected to the armature of the generator or the turbine needs to be connected to a spindle or rotor which in turn is connected to the armature. It is important that the armature rotates at the same rate as turbine (Standard Generator Design). 0006 The electricity that the generator creates is directed into a transformer which decreases or increases the voltage (See 2-B, Sheet 1 and 2). Either way the electricity that comes from transformer is directed into some kind of switch gear device (See 2-D, Sheet 1 and 2). This device regulates and directs the electric power. An electric meter of some sort could be used to measure the amount of electricity that comes from the switch gear device (See 2-E, Sheet 1 and 2). This excess power goes into the power grid through power line (See 2-F, Sheet 1 and 2). 0007 This unit does require initial start-up. There is a lot of ways of doing this from batteries other generators, or from any standard power source (See 1-A, Sheet 1 and 2). Any excess power can be stored in batteries, so that if you use the device on a regular basis, the batteries would be able to start the device at anytime (See 2-C, Sheet 1 and 2). An alternating current (AC) generator would work best if you are transferring electricity into the power grid (See 2-F, Sheet 1 and 2) or you’re transporting the electricity over a long distance. 0008 The turbine design is very important. I think the Pelton, Harris Nautilus, Neptune and the Banki turbines would work excellent with my concept. The Kaplan, Francis and basic water wheels would also be good choices in my opinion. 0009 I have designed my own turbine. It is called the Pinwheel turbine (See 1-F, Sheet 2). This design is patterned after the Pinwheel firework. I believe the best position for the Pinwheel Turbine is horizontal with the spindle or armature being vertical but I believe a vertical position would be very efficient, too. The spindle or armature would be horizontal if turbine was vertical. The type of generator would determine the best position of the turbine and the type of turbine to be used. 00010 My design has the disc being solid even though a spoke design could be effective, too. The round disc design has to be strong and sturdy to withstand high pressure over a prolonged period of time. I believe the disc should have at least 12 receptor cones positioned around the perimeter of the disc (dimensions are patterned after the Pinwheel firework). These receptors should be spaced evenly. I also believe that the receptors should point slightly outward from the disc for maximum retention of the thrust from water coming from the pump. The size of the disc turbine shouldn’t be much larger in diameter than the width of the generator on which it is connected (just not too big or small for maximum efficiency of rotation in which torque is created. Claims 1. I claim my concept of using pressurized water is a highly efficient

ways of generating Electric Power.

Abstract of the Disclosure My concept of using pressurized water to generate electric power is more efficient and is environmentally friendly than other methods in use today. Thrust from water flow would produce torque by rotating the turbine which is connected to an electric generator. I believe this method to be more efficient than steam, internal combustion, or coal burning methods. Sequence Listing for Self-Powered Hydro-electric Power

Generator

Basic formula is voltage (power to run pump) = X-Amount PSI (Pounds Per Square Inch Pressure) = X-Amount Torque = X-Amount Power Generated = X-Amount. Pressure from thrust of water coming from water pump through the water pump nozzle X-Amount of pressure on turbine that is attached to generator Torque created by turbine (which is being rotated by thrust of water from water pump) = X-Amount Generator converts torque into electricity which in turn runs the pump 1/6 of Torque = Horsepower

I believe Amperage created by the Generator will be greater than Amperage needed to run the pump. I realize there will be some friction loss when turbines rotate. I believe between 10 and 20 percent. With certain turbines you can line-up a second turbine to receive excess water pressure from water flow that receptors on first turbine didn’t capture. Second turbine will rotate a lot less but still can contribute to power output DRAWINGS

Robert Jackson Title of Invention Self Powered Hydro Electric.doc Robert Jackson Cadd Drawing.doc Robert Jackson -Self-Powered-Hydro-Electric-Power Generator 60-363271.pub |