Title of Invention:

Pinwheel Turbine

Pin Wheel Turbine Patent Application 10-637903

Name of Inventor:

Robert William Jackson

A Citizen of the United States of America

Address of Inventor:

3309 Jomar Drive

Plano, Texas 75075

Prior Address of Inventor: RR 2, Box 142

Hinton, Oklahoma 73047

CROSS REFERENCE TO RELATED APPLICATION

This application is based on the following provisional patent application.

Title: Pinwheel Turbine

Patent Number 60/409171 Filing Date: 9-9-2002

The application related to the following provisional patent

Title: Municipal Hydroelectric Power Generator Patient Number 60/402424

Filing Date: 8-10-2002

This application is related to the following provisional patent

Title: Self-Powered Hydroelectric Generator Patent Number 60/363271

Filing Date: 3-11-2002

This application is related to the following provisional patent

Title: Self-Powered Air-Driven Electric Generator Patent Number 60/368394

Filing Date: 3-29-2002

This application is related to the following non-provisional application

Title: Self-Powered Hydro-Electric Generator Patent Number 10/136521

Filing Date: 5-1-2002

This application is related to the following non-provisional application

Title: Self-Powered Air-Driven Electric Generator Patent Number 10/136063

Filing Date: 5-1-2002

Robert William Jackson requests that Disclosure Document number 506280

also be included in the examination of this application. Title:

Self-Powered Hydro-Electric Generator. Filing Date: 2-28-2002.

Robert William Jackson requests that Disclosure Document number

514683 also be included in the examination of this application. Title:

Emergency Hydro-Electric Generator. Filing Date: 7-8-2002.

Robert William Jackson requests that Disclosure Document number

512933 also be included in the examination of this application. Title:

Municipal Water Supply Generator System. Filing Date: 6-6-2002.

STATEMENT REGARDING FEDERALLY SPONSORED RESEARCH OR DEVELOPMENT

"Not Applicable"

REFERENCE TO SEQUEL LISTING, A TABLE, OR A COMPUTER PROGRAM LISTING

COMPACT DISC APPENDIX

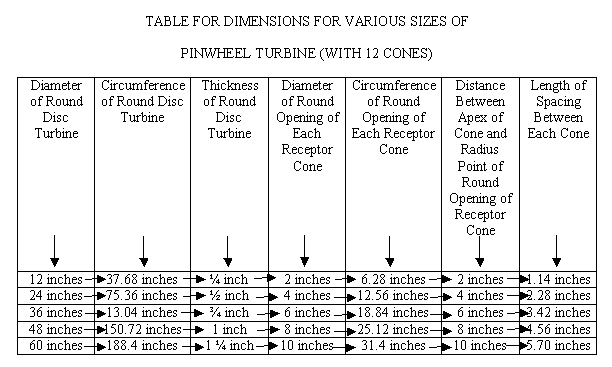

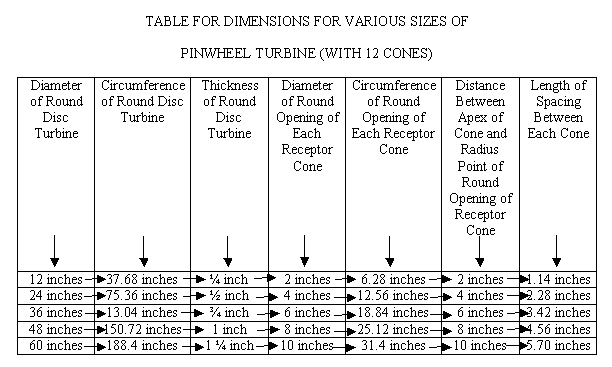

TABLE FOR DIMENSIONS FOR VARIOUS SIZES OF

PINWHEEL TURBINE (WITH 12 CONES)

Diameter of Round Disc Turbine Circumference of Round Disc Turbine Thickness

of Round Disc Turbine Diameter of Round Opening of Each Receptor Cone Circumference

of Round Opening of Each Receptor Cone Distance Between Apex of Cone and

Radius Point of Round Opening of Receptor Cone Length of Spacing Between

Each Cone

12 inches 37.68 inches ¼ inch 2 inches 6.28 inches 2 inches

1.14 inches

24 inches 75.36 inches ½ inch 4 inches 12.56 inches 4 inches

2.28 inches

36 inches 13.04 inches ¾ inch 6 inches 18.84 inches 6 inches

3.42 inches

48 inches 150.72 inches 1 inch 8 inches 25.12 inches 8 inches 4.56

inches

60 inches 188.4 inches 1 ¼ inch 10 inches 31.4 inches 10 inches

5.70 inches

BACKGROUND OF THE INVENTION

This invention deals with generating electricity. This turbine

could be used with most generators in use today.

I thought of this design for this turbine on the 4th of July

2001. I noticed the efficiency of the rotation of a pinwheel firework.

At the time I had some ideas about generating electricity with water and

air. I combine the concepts and developed some plans. I started

a timeline on October 15, 2001, dealing with these concepts and this particular

turbine. I documented my efforts by mailing information to myself.

On or around January 21, 2002, I attempted to get a provisional

patent. I met with 2 different patent attorneys and called many more.

One of the patent attorneys said he would help me if I had a

drawing made up. I was confused. I thought a drawing was required.

It took about a month for a mechanical engineer to get this project done.

I ordered the patent kit from the patent office around 1-23-2002.

It took over 2 weeks to get to me. I mailed a Disclosure Document

on 2-11-2002 that deals with this turbine. Filing date 2-28-2002.

Document number 506280.

After paying the lawyers and mechanical engineer fees I didn't

have enough money to hire the lawyer to submit my provisional patent.

I submitted my own patent application. Filing date 3-11-2002,

patient application number 60/363271. This patent application is

the first one on file for me that deals with this turbine. I list

this turbine in numerous other applications. I believed this

turbine is unique and is a good design.

BRIEF SUMMARY OF THE INVENTION

This is a high pressure turbine. This design is for high PSI (Pounds

per Square Inch) pressure coming from either air or water. The theory

is to create the most RPM's (Revolutions Per Minute) with this thrust of

pressure in the most efficient manner.

This turbine needs to be attached to a generator in which RPM's

determine power output. I call this turbine the pinwheel because

of its basic design is pattern after this firework. This design has

12 receptor cones.

BRIEF DESCRIPTION OF THE SEVERAL VIEWS OF THE DRAWING

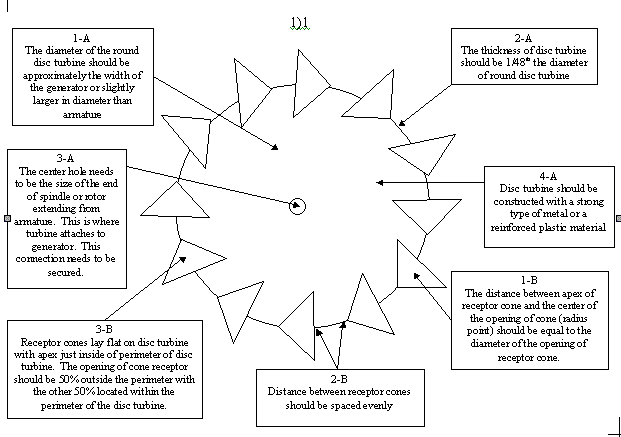

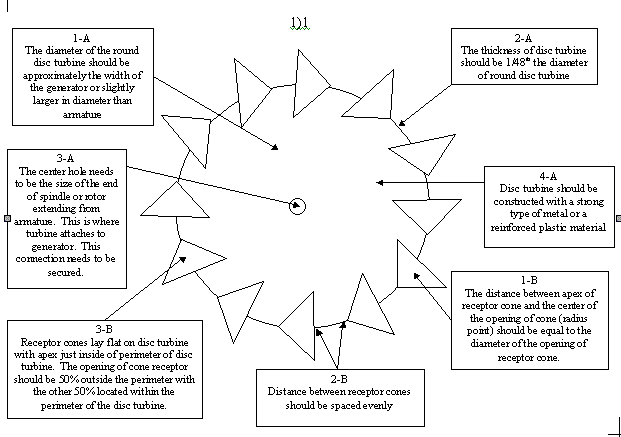

1-A – Diameter of disc dimensions

2-A – Thickness of disc turbine

3-A – Center hole dimensions

4-A – Material used in making of Pinwheel Turbine

1-B – Receptor cone dimensions

2-B – Spacing between receptor cones

3-B – Position of receptor cones

DETAILED DESCRIPTION OF THE INVENTION

0001 The basic design is patterned after the pinwheel firework.

My design is a solid disc. This disc should have 12 receptor cones

positioned around the perimeter (circumference) of the round disc (See

chart on page 5). These receptors should be spaced evenly (see 2-B).

0002 The turbine should be constructed with a strong metal or a reinforced

plastic material (See 4-A).

0003 The diameter of the round disc turbine should be approximately

the width of the generator or slightly larger in diameter than Armature

(See 1-A). This is calculated when turbine is vertical and generator

is horizontal or turbine is horizontal and generator is vertical.

The spindle or rotor extending from Armature should be center point for

measuring this dimension. This is where turbine attaches to generator.

0004 The thickness of disc turbine should be 1/48th the diameter of

round disc turbine (see Box 2-A).

0005 The center hole needs to be the size of the end of spindle or

rotor that extends from Armature. This is where turbine attaches

to generator. This connection needs to be secured. (See 3-A).

0006 The center hole should be approximately 1/10 the diameter of disc

turbine, but this could vary due to size of generator to which it is attached.

0007 The distance between apex of receptor cone and the center of the

opening of cone (radius point) should be equal to the diameter of the opening

of

receptor cone. (See 1-B)

0008 Receptor cones lay flat on disc turbine with apex just inside

of perimeter of disc turbine. The opening of cone receptor should

be 50% outside the perimeter with the other 50% located within the perimeter

of the disc turbine. (See 3-B)

0009 The disc turbine and the receptor cones needs to be either one

solid object or receptor cones needs to be securely attached to round disc

turbine.

00010 This turbine is similar to the Pelton hydro-electric turbine.

I claim my turbine is different because I use cones instead of buckets

as the receptors. This is the only turbine that is similar to mine

that I'm aware of.

CLAIMS

(1) I claim this turbine can be used with the thrust of air or water.

(2) I claim this turbine can be adapted and can be used with most generators

on the market today.

(3) I claim this turbine can be used with a newly designed generator.

ABSTRACT OF THE DISCLOSURE

I designed this turbine to be used with pressure (thrust) from

water that emits from water pumps or air that emits from air compressors.

This pressure (thrust) is directed at point of turbine which creates the

most efficient rotation (RPM's) of turbine which is attached to a generator.

BOXES FOR DRAWING

BOXES FOR DRAWING

Box-1-A-The diameter of the round disc turbine should be approximately

the width of the generator or slightly larger in diameter than armature.

Box-2-A-The thickness of disc turbine should be 1/48th the diameter

of round disc turbine.

Box-3-A-The center hold needs to be the size of the end of spindle

or rotor extending from armature. this is where turbine attaches

to generator. This connection needs to be secured.

Box-4-A-Disc turbine should be constructed with a strong type of metal

or a reinforced plastic material.

1-B-The distance between Apex of receptor cone and the center of the

opening of cone (radius point) should be equal to the diameter of the opening

of receptor cone.

2-B-Distance between receptor cones should be spaced evenly.

3-B-Receptor cones lay flat on disc turbine with apex just inside of

perimeter of disc turbine. the opening of cone receptor should be

30% outside the perimeter with the other 50% located within the perimeter

of the disc turbine.

|