| Aquarius | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sea-launched orbital launch vehicle.

Proposed expendable, water launch, single-stage-to-orbit, liquid oxygen/hydrogen, low-cost launch vehicle designed to carry small bulk payloads to low earth orbit. A unique attribute was that low reliability was accepted in order to achieve low cost. The Aquarius Concept was launch of low-cost supplies on a low-cost vehicle. These would be low-cost, easily-replaced consumables such as water, fuel, food, and air as needed by the International Space Station and military spacecraft. Launch failures would be acceptable since the intrinsic value of the replaceable consumables was low. About one-third of the launches were expected to fail The lowest-cost vehicle was a single-string, single-stage, single-engine low-margin vehicle built using non-white-glove labor and facilities. Low margins were consistent with a one-third failure. The loss-tolerant payload and vehicle required an appropriate supporting infrastructure. An ocean-based floating launch infrastructure was low-cost and tolerated failures. Orbital retrieval of the payload would be by a space-tug (e.g. the ASTRO vehicle then being developed by the DARPA Orbital Express program, or other vehicles being studied under the NASA Alternate Access to Station study. Practical vehicle sizing led to a ~1 metric ton palletized payload to 200 km circular orbit with 52 deg inclination (Space Station). The cost target: $600K per launch at ~100 launches per year. The Aquarius concept of low-cost/low-reliability launch of consumables was create in late 1998. In August 1999 the first technical paper was presented on Aquarius, included estimated performance and size of vehicle from launch simulations. In May 2000 the FAA Office of Commercial Space Licensing indicated that they had no problem with the concept as long as no recovery at sea. In the summer of 200 NRL indicated that Aquarius avoided the recovery 'show-stopper' encountered on the previous U.S. Navy SEALAR floating launch program. In February 2001 a meeting at DARPA indicated technical interest: 'the Aquarius rocket science was fine', but concerns as to cost and economic viability remained. In April 2001 the State of California awarded a Space Grant to the Space Systems/Loral team for study of the economic value of the Aquarius concept In May 2001 an Space Systems/Loral-Microcosm paper was presented on cost as a function of reliability for existing launchers and cost projections for low-reliability launch. By the fall 2001 the Aquarius supply concept was included in DARPA-funded studies and proposals for consumables delivery for Orbital Express program. In April 2002 U.S. Patent No. 6,360,993 was granted to SS/L for the Aquarius concept. In 2005 Space Systems/Loral, in conjunction with Aerojet and ORBITEC started work on a $1-million study funded by a provision of a defense appropriations bill on new engine technologies for use on Aquarius. The study is focusing on the development of a vortex combustion cold wall engine, using LOX and liquid hydrogen propellants; the engine would provide high thrust while eliminating the need for costly ablative materials in engine components. The study was scheduled to conclude in 2006. The Space Grant Study Team consisted of:

Wilson Composite Technologies, Folsom, CA: Composite tank manufacturing expertise Aquarius had to be seen in the context of the Evolving Space Launch Infrastructure. In productive use of space, total mass launched would always be a mix of . If feasible, the cost of launching the inexpensive stuff should be commensurate with its low intrinsic value - "Bread was delivered by a bread truck, not a Brinks truck". Within the current state of technology this implied a reduced-reliability launcher. A cheap, workhorse consumables launcher helped increase the high-reliability launch systems' revenue-generating capacity for launching mission-specific hardware by 50-100%. The hi-reliability launcher would carry spacecraft dry or nearly dry and thus carry only expensive mission elements (often <50% of total mission wet mass). The reduced-reliability launcher carried the low-cost propellants at low cost. Thus, low-reliability and high-reliability launchers coexist synergistically. ISS consumables demand alone supported between 17 and 80 metric tons of basic supplies annually, or 20 to 100 Aquarius launches per year. Single Stage to Orbit (SSTO) was found to have a lower development cost and operational cost but incurred a greater risk during development. Cost was lower because the design was simpler, the parts count was lower, and the operational activity was reduced. But SSTO had a higher development risk because of the low mass margin of the vehicle - mass growth beyond 0.5 metric tons would reduce the payload to be delivered to orbit below the 1.0 metric ton goal. From a business perspective the SSTO recurring cost savings justified the investment to seriously evaluate SSTO. An analysis was performed to evaluate four schemes, all capable of delivering 1.0 metric ton payload to orbit:

Four candidate schemes were evaluated for Aquarius. The total vehicle liftoff mass for the SSTO-K was an order of magnitude greater than for all other vehicles SSTO vs TSTO - Results from Spreadsheet Analysis

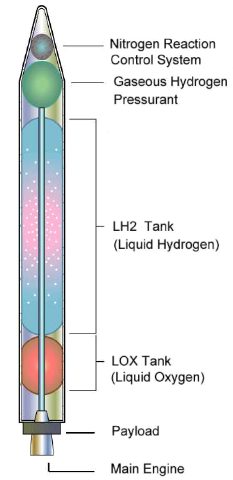

Final Launch Vehicle Design Baseline for Study:

Production and transportation baselines were established after a trade study of alternatives and discussions with government and commercial entities as regards costs and feasibility of various construction site and transportation modes. An inland factory site would be established at Palmdale. Land cost there would be half that of a waterfront site, and aerospace worker salaries were comparable to waterfront area salaries. After 2002, this would not longer be the site of the Space Shuttle processing facility, therefore underutilized capacity existed. Palmdale was 90 railroad miles from the selected Long Beach transshipment point. It was already the home port of Sea Launch Corporation, which launched Ukrainian Zenit-3SL vehicles from a floating platform in the mid-Pacific. Crowley Marine Services already conducted barge operations here The Floating Launch approach avoided risk to launch support facilities. Failure could occur at or near liftoff since there was no land-based launch pad or sea-based platform to be harmed by a launch accident. The barge and all other support equipment can be removed from the launch area to a safe distance prior to launch. The same barge was used for transport was reconfigured for launch support. The vehicle was loaded on the barge unfueled and was fueled aboard the barge. The barge crew initiated fueling and then departed - the barge was uncrewed during launch support. The vehicle was floated off the barge for deployment prior to launch. The aft end of the barge was submerged by flooding ballast tanks in hull - a modification of the technique used by Crowley to deliver bridge pylons. The vehicle was erected using low-cost, low-tech means. Ballast used to erect the vehicle was carried aboard the support barge and consisted of about 50 tons of sand in a biodegradable container. It would be abandoned after launch, sinking to the bottom of the sea. This approach was used to support U.S. Navy Project Hydra launches in the 1960s and the commercial Dolphin sounding rocket launch in 1984. A conceptually similar technique was used currently to erect Proton launchers, which were erected by a low-cost pulled cable The launch area would be off Hawaii to allow all orbital azimuths to be attained and to avoid shipping lanes. A modest launch support harbor at an unimproved 'Coral Stockpile' near Kawaihae in an area already industrialized would be built. Development costs were estimated as follows:

The Aquarius concept for reduced-reliability, cost-optimized launch of consumables was technically feasible, but achievability of the most cost-effective SSTO version remained to be demonstrated. The Aquarius concept was economically viable and competitive within the identified market. Deployment of a consumables "pipeline to space" was relied upon by several missions under development but was not currently funded by the associated customers. Aquarius had substantial value to the State of California in economic activity and job creation. Manufacturer: Space Systems/Loral. LEO Payload:

1,000 kg (2,200 lb). to: 370 km Orbit. at: 52.00 degrees.

Total Mass: 130,000 kg (280,000 lb). Core Diameter: 4.00

m (13.10 ft). Total Length: 43.00 m (141.00 ft). Span: 4.00

m (13.10 ft). Boost Propulsion: Lox/LH2. Development Cost $:

700.000 million. in: 2002 average dollars. Launch Price $:

1.000 million. in: 2002 price dollars. Cost comments: Development

cost includes $550 million for orbital depot and space tug to move payloads

from delivery orbit to storage depot or ISS.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Contact

us with any corrections, additions, or comments.

Conditions for use of drawings, pictures, or other materials from this site.. To contact astronauts or cosmonauts. © Mark Wade, 1997 - 2007 except where otherwise noted. |