Directed Energy Weapons

Project Shiva Nova

|

Creating a Miniature Star

on Earth

Photo Credit: National

Ignition Facility (NIF)

Most tours of NIF begin at the

Visitor Center, which showcases NIF technology and describes the overall

operation of the laser. Actual NIF optics and a 1/10 scale model of the

target chamber are on display here.

Creating a miniature star on

Earth: that's the goal of the National Ignition

Facility (NIF), the world's largest laser. When completed in 2009, NIF

will focus the intense energy of 192 giant laser beams on a BB-sized target

filled with hydrogen fuel – fusing, or igniting, the hydrogen atoms' nuclei.

This is the same fusion energy process that makes the stars shine and provides

the life-giving energy of the sun. NIF is a program of the U.S. Department

of Energy's National Nuclear Security Administration.

National Ignition

Facility (NIF) - SECURE SITE

Lawrence Livermore National

Laboratory • 7000 East Avenue • Livermore, CA 94550, Operated by Lawrence

Livermore National Security, LLC for the Department of Energy's National

Nuclear Security Administration

Inertial

Confinement Fusion: How to Make a Star - SECURE

SITE |

Photo Credit: National

Ignition Facility (NIF)

Lawrence Livermore National Laboratory

is located in Livermore, California, about 40 miles east of San Francisco

in southern Alameda County. The National Ignition Facility is in the northeast

corner of the Laboratory, at the bottom right corner in the photo.

Photo Credit: National

Ignition Facility (NIF)

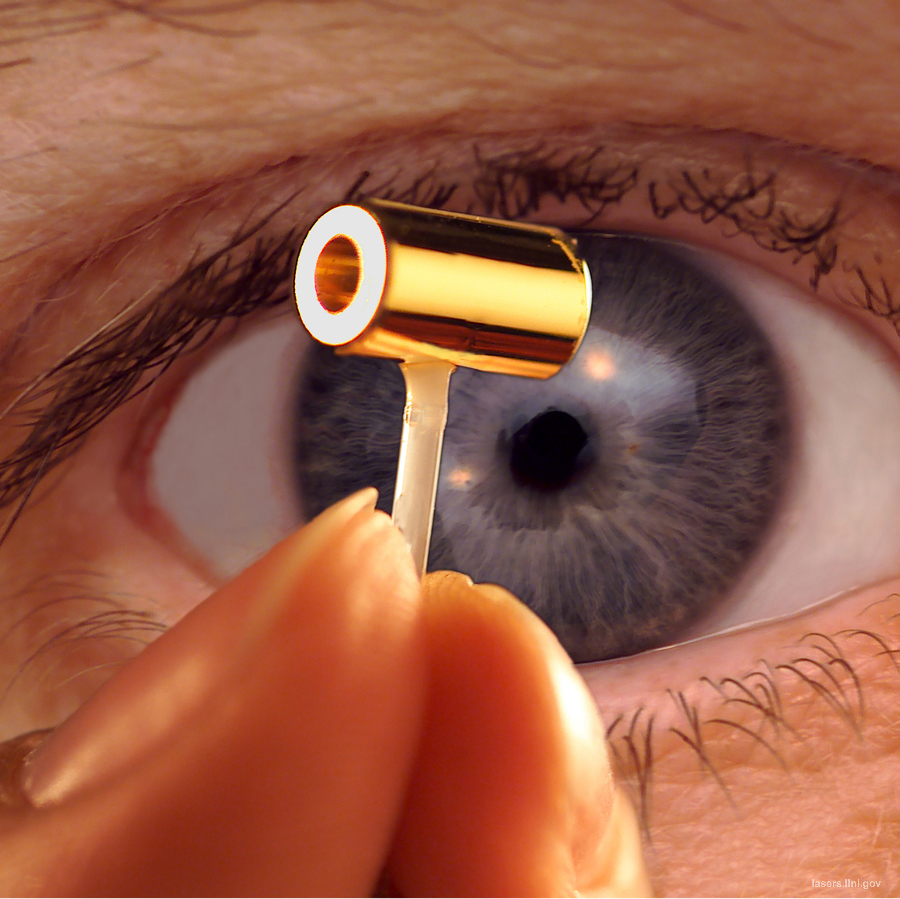

A NIF hohlraum. The hohlraum

cylinder, which contains the NIF fusion fuel capsule, is just a few millimeters

wide, about the size of a pencil eraser, with beam entrance holes at either

end. The fuel capsule is the size of a small pea.

Photo Credit: National

Ignition Facility (NIF)

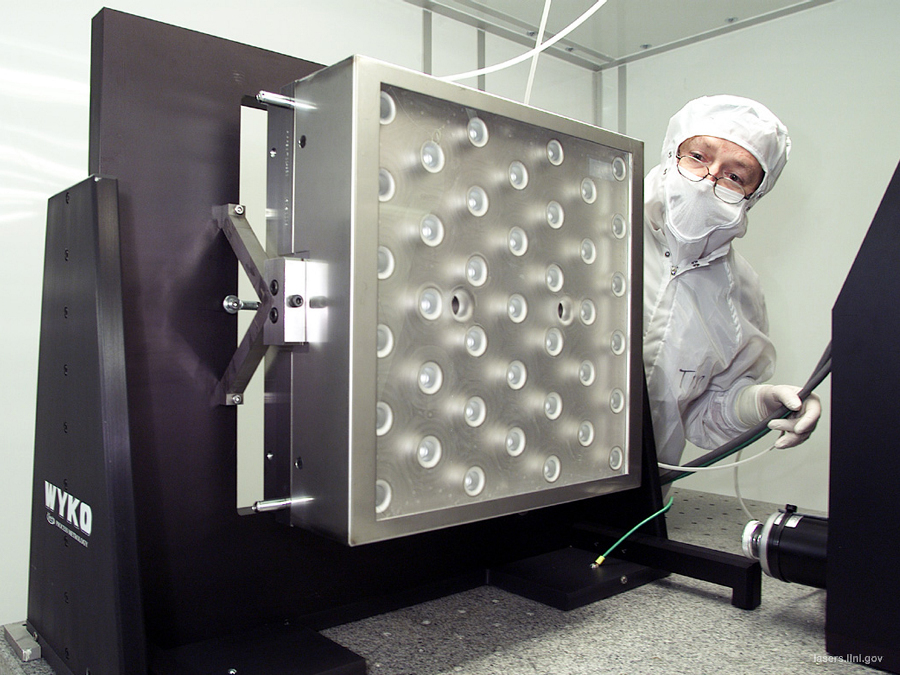

Deformable mirrors, located at

the ends of the NIF main amplifiers, use an array of 39 actuators to create

a movable surface that corrects aberrations in a beam due to minute distortions

in the optics.

Photo Credit: National

Ignition Facility (NIF)

Laser Bay 2, one of NIF's

two laser bays, was commissioned on July 31, 2007.

Photo Credit: National

Ignition Facility (NIF)

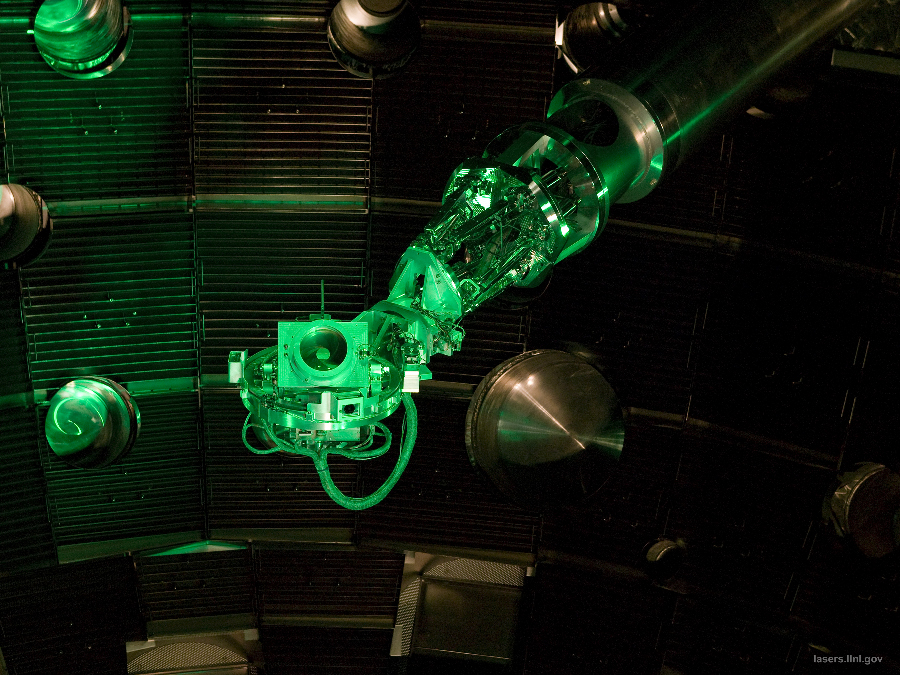

The interior of the NIF target

chamber. The louvered "first wall" protects the structure from possible

flying debris during shots. The target positioner, which holds the target,

is on the right.

Photo Credit: National

Ignition Facility (NIF)

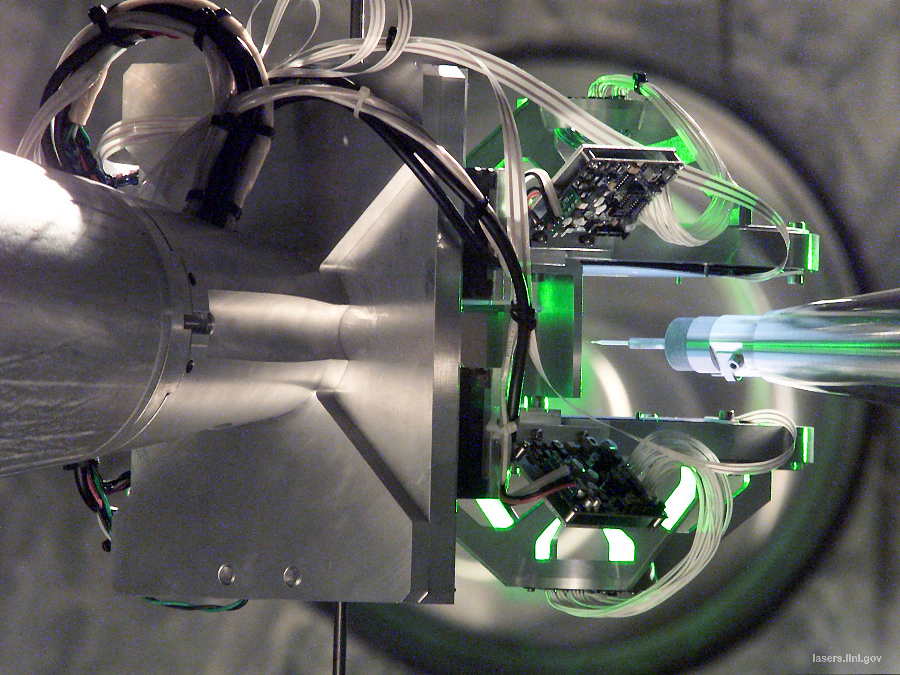

The target positioner and target

alignment system precisely locate a target in the NIF target chamber. The

target is positioned with an accuracy of less than the thickness of a human

hair.

Photo Credit: National

Ignition Facility (NIF)

The fabrication of melted and

rough-cut blanks of laser glass amplifier slabs needed for NIF construction

(3,072 pieces) was completed in 2005. The amplifier slabs are neodymium-doped

phosphate glass manufactured by Hoya Corporation USA and Schott Glass Technologies.

Photo Credit: National

Ignition Facility (NIF)

The Laser and Target Area Building

is the size of three football fields.

Photo Credit: National

Ignition Facility (NIF)

This artist's rendering shows

a NIF target pellet inside a hohlraum capsule with laser beams entering

through openings on either end. The beams compress and heat the target

to the necessary conditions for nuclear fusion to occur. Ignition experiments

on NIF will be the culmination of more than 30 years of inertial confinement

fusion research and development, opening the door to exploration of previously

inaccessible physical regimes.

Photo Credit: National

Ignition Facility (NIF)

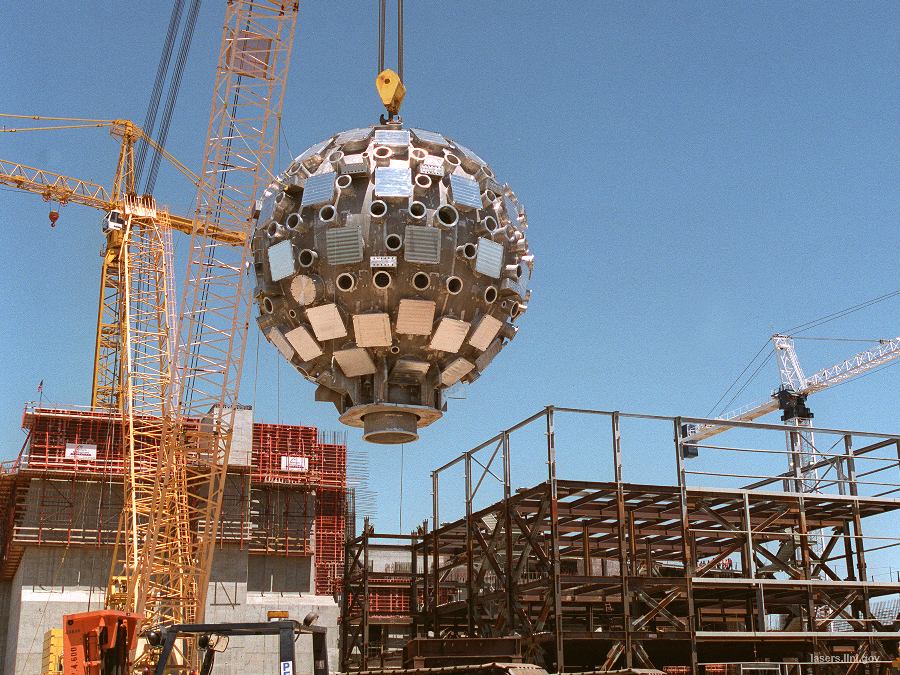

The 10-meter-diameter target

chamber, installed in June 1999, weighs 287,000 pounds. The spherical vacuum

vessel was assembled from 18 four-inch-thick aluminum sections fabricated

by Pitt-Des Moines, Inc., of Pittsburgh, Pennsylvania, and was installed

with one of the largest cranes in the world.

Photo Credit: National

Ignition Facility (NIF)

NIF's final optics inspection

system, when extended into the target chamber from a diagnostic instrument

manipulator, can produce images of all 192 beamline final optics assemblies.

Photo Credit: National

Ignition Facility (NIF)

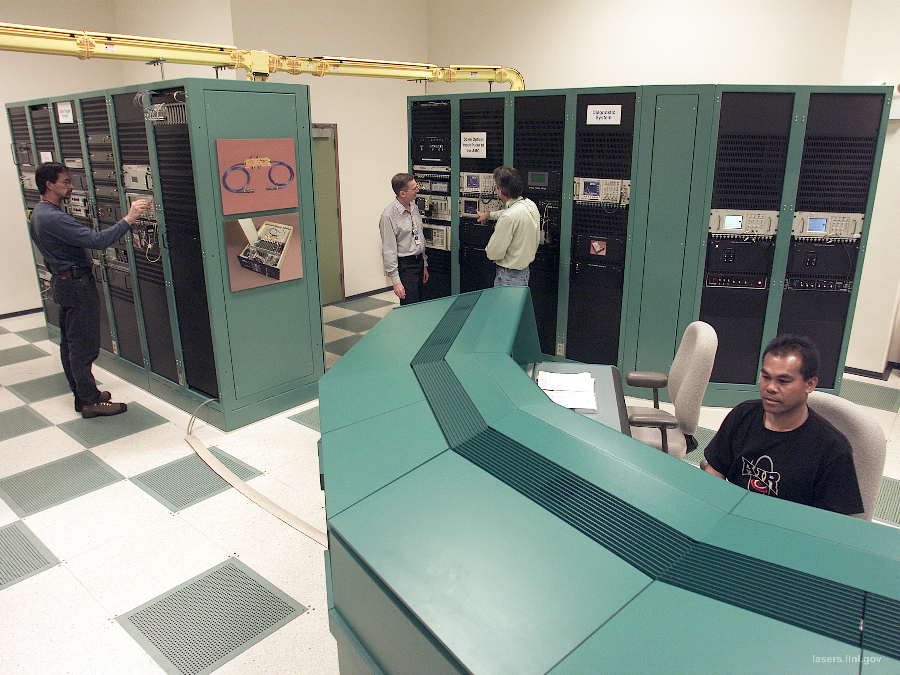

The NIF Control Room. NIF's complex

operation, alignment and diagnostic functions are controlled and orchestrated

by the integrated computer control system. It consists of 300 front-end

processors attached to nearly 60,000 control points, including mirrors,

lenses, motors, sensors, cameras, amplifiers, capacitors and diagnostic

instruments. The shot director (left) must coordinate all 14 NIF subsystems

when preparing for a shot.

Photo Credit: National

Ignition Facility (NIF)

NIF & Photon Science Principal

Associate Director Ed Moses honors a NIF contract worker by presenting

him with the final "golden bolt" representing completion of the beampath

installation in Switchyard 1 in August 2003.

Photo Credit: National

Ignition Facility (NIF)

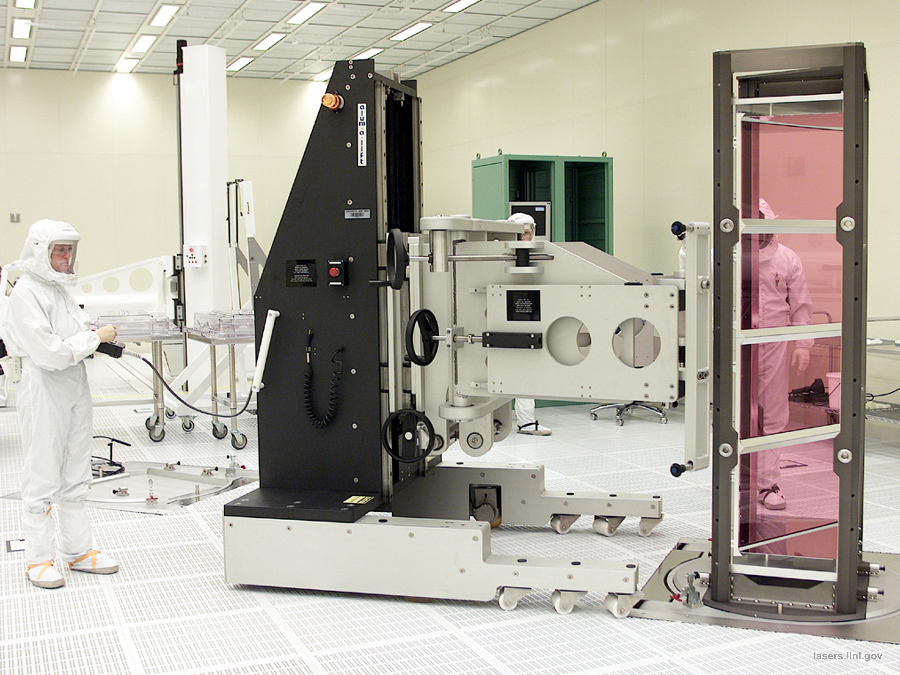

The laser bay transporter, an

automated guided vehicle, is used to install canisters containing amplifier

slab cassettes, known as line replaceable units, into the main amplifier

frame assembly units.

Photo Credit: National

Ignition Facility (NIF)

This potassium dihydrogen phosphate

(KDP) crystal, weighing almost 800 pounds, was produced through a newly

developed rapid-growth process that takes only two months, as opposed to

two years using conventional methods. Each crystal is sliced into 40-centimeter-square

crystal plates. More than 600 of these plates are needed for NIF.

Photo Credit: National

Ignition Facility (NIF)

In the summer of 2005, the fabrication

of melted and rough-cut blanks of amplifier slabs needed for NIF construction

(3,072 pieces) was completed. The amplifier slabs are neodymium-doped phosphate

glasses manufactured by Hoya Corporation USA and Schott Glass Technologies.

A novel, continuous melting process was used to make the meter-sized plates

of laser glass at a rate 20 times faster, five times cheaper, and with

two to three times better optical quality than with the previous one-at-a-time,

"discontinuous" process.

Photo Credit: National

Ignition Facility (NIF)

This is a laser glass slab in

a line replaceable unit (LRU) that was assembled in the Optics Assembly

Building cleanroom. An LRU is a large metal frame that holds various types

of lenses, mirrors or glass that can be easily installed in a beamline

or removed for maintenance. This glass slab LRU will be installed between

two flashlamp cassettes that fire as the laser beam passes through, causing

the beam to pick up energy from the specially treated glass on its way

to the target chamber.

Photo Credit: National

Ignition Facility (NIF)

NIF laser pulses are born in

the master oscillator room, in which a compact laser oscillator generates

low-energy (a few nanojoules) laser pulses. The oscillator pulse is shaped

in time and frequency-broadened, using the small range of multiple wavelengths

produced in the fiber laser, to help smooth the intensity of the laser

beam when it is ultimately focused on the target. There are 48 independent

pulse shaping systems, and each of the pulses is transported on separate

fiber optic cables to 48 preamplifier modules for further amplification.

Photo Credit: National

Ignition Facility (NIF)

In 2009, construction of the

National Ignition Facility will be complete. Experiments already will have

begun in support of the nation's nuclear weapon Stockpile Stewardship Program

as well as to study high energy density physics and astrophysical phenomena

and to begin laying the groundwork for fusion energy power production. |

| Clean Construction Protocol

for the National Ignition Facility Beampath and Utilities

Journal of the IEST

Issue: Volume 46, Number 1 / 2003

Pages: 85 - 97

Stanley C. Sommer A1, Irving F. Stowers A1, David E.

Van Doren A2

A1 Lawrence Livermore National Laboratory

A2 Jacobs Facilities Incorporated

Abstract:

When the stadium-size National Ignition Facility (NIF)

is fully operational at the Lawrence Livermore National Laboratory (LLNL),

its 192 laser beams will deliver 1.8 megajoules (500 terawatts) of energy

onto a target to create extremely high temperatures and pressures for inertial

confinement fusion research as part of the Stockpile Stewardship Program.

Due to the performance threshold and requirements of the NIF optical components,

the optics and their surrounding beampath as well as the supporting utility

systems must be fabricated, cleaned, assembled, and commissioned for precision

cleanliness. This paper will provide an overview of the NIF cleanliness

requirements, the Clean Construction Protocol (CCP) specifications for

the beampath and clean utilities, and techniques for verifying the CCP

specifications.

The NIF cleanliness requirements define limits for

molecular and particulate contamination. The goal of these limits is to

prevent contamination of optical components. To prevent laser-induced damage

and poor laser quality in the optical components, requirements for cleaning,

assembly, installation, and commissioning in terms of particle and nonvolatile

residue (NVR) levels are defined. The airborne cleanliness requirements

in the interior of the beampath are Class 1 (ISO Class 3) particulate levels

and a few parts-per-billion (ppb) airborne molecular contamination (AMC)

(SEMI F21-95 MC-1,000).

To achieve the cleanliness requirements for the beampath

interior, a graded CCP approach is used as the NIF beampath and utilities

are being constructed by a partnership between LLNL and the construction

contractor, Jacobs Facilities Inc. (JFI) in a stadium-size Class 100,000

(ISO Class 8) building. Installation of the beampath components utilizes

localized mini-environments of Class 100 (ISO Class 5) or better, with

budgets of cleanliness exposure or "class-hours" for each clean connection.

Garment, equipment, and operational considerations are evaluated with process

verification.

Verification of the beampath and utility cleanliness

is performed with cleanliness exposure monitoring, evaluating particulates

with "swipes" and the LLNL-developed Precision Cleanliness Verification

System (PCVS), and measuring nonvolatile residues (NVRs) and AMCs with

analytical chemistry techniques. Cleanliness verification results demonstrate

that the CCP specifications are achieving the NIF cleanliness requirements

for the beampath and clean utilities.

PDF Files

Clean

Construction Protocol for the National Ignition Facility Beampath and Utilities

- (Archived)

Sixth

Conference on Engineering Aspects of Lasers and Their Application

- (Archived)

V. V. Aleksandrov and V. Yu.

Baranov

Translated from Atomnaya Énergiya,

Vol. 44, No. 2, pp. 194–196, February, 1978

Shiva

Nova Organization - (Archived) |

| Empowering Light - Historic

Accomplishments in Laser Research

Excerpt...

In 1974, Livermore finished the one-beam, 10-joule

Janus laser and used it to conduct the first fusion experiments at the

Laboratory. It was used to demonstrate for the first time the thermonuclear

reaction in laser-imploded deuterium–tritium fuel capsules. Starting in

1974, the two-beam Janus laser was used to gain a better understanding

of laser–plasma physics and thermonuclear physics. It was also used to

improve the LASNEX computer code, a hydrodynamics code developed in the

1970s for laser fusion predictions, which is still in use today.

The one-beam Cyclops was also completed in 1974. Its

beamline was a prototype of the yet-to-be built Shiva laser.

..

From 1973 to 1977, the Laboratory

built four laser systems: (a) the one-beam Cyclops; (b) the one- and two-beam

Janus system, which is still in use; (c) the two-beam Argus; and (d) the

20-beam Shiva. Each new laser provided more power and better control over

the target-irradiation conditions as well as produced higher temperatures

and greater compression and density in the deuterium–tritium fuel than

its predecessor.

Excerpt...

The 20-beam Shiva became the world’s most powerful

laser in 1977, delivering 10.2 kilojoules of energy in less than a billionth

of a second in its first full-power firing. In June 1979, Shiva compressed

fusion fuel to a density of 50 to 100 times greater than its liquid density.

Even more important, according to John Holzrichter, who was responsible

for the laser and ICF programs at the time, Shiva proved once and for all

that infrared laser light was too long a wavelength to reach fusion energy

gain. Says Holzrichter, “The laser beam generates a dense plasma where

it impinges on the target material. The laser light gives up its energy

to the electrons in the plasma, which absorb the light. The rate at which

that happens depends on the wavelength and the intensity. On Shiva, we

were heating up electrons to incredible energies, but the targets were

not performing well. We tried a lot of stuff to coax the electrons to transfer

more of their energy to the target, with no success.”

...

This miniature “star”

was created in the Nova laser target chamber as 300 trillion watts of

power hit a 0.5-millimeter-diameter

target capsule containing deuterium–tritium fuel.

Excerpt...

Ten times more powerful than Shiva, Nova became the

world’s most powerful laser. In 1986, Nova produced the largest laser fusion

yield to date—a record 11 trillion fusion neutrons. The following year,

Nova compressed a fusion fuel target to about one-thirtieth of its original

diameter, close to that needed for ignition and fusion gain. In 1996, one

arm of Nova was reconfigured as a petawatt laser. (See S&TR, March

2000, The Amazing Power

of the Pettawatt; December 1996, Crossing

the Petawatt Threshold.) Record-setting laser shots produced pulses

with more than 1.3 quadrillion watts, or 1.3 petawatts, of peak power.

The laser pulse lasted less than 0.5 trillionth of a second—more than a

thousand times shorter than shots typically produced by Nova’s 10 beams.

Excerpt...

When the United States ceased

nuclear testing, laser facilities became even more important for defense

research, and the portion of Nova shots dedicated to the weapons program

increased considerably. Researchers using Nova continued obtaining high-energy-density

data necessary to validate the computer codes used to model nuclear weapons

physics.

SOURCE: Science &Technology

Review

September 2002 Empowering

Light - Historic Accomplishments in Laser Research

Ten times more powerful than

Shiva, Nova became the world’s most powerful laser. .....

Update:

Super Laser at the National

Ignition Facility - KQED QUEST

Youtube

Link

World's Most Powerful Laser Unveiled

Youtube

Link

The world's most powerful

laser was dedicated at the Livermore National Laboratory in California.

It's designed to shore up the nation's aging nuclear weapons. (May 29)

Related Articles

-

Energy & Technology Review

-

Science &Technology Review

-

September 1996, Taking

Lasers beyond the National Ignition Facility

-

November 1996, The

Secrets of Crystal Growth

-

December 1996, Crossing

the Petawatt Threshold

-

September 1998, The

X-Ray Laser: From Underground to Tabletop

-

October 1998, Blasts

of Light to Strengthen Metals

-

January/February 1999, Leading

the Best and the Brightest

-

July/August 1999, A

New View of the Universe

-

September 1999, Target

Chamber’s Dedication Marks a Giant Milestone

-

November 1999, Extreme

Ultraviolet Lithography–Imaging the Future

-

March 2000, The

Amazing Power of the Pettawatt

-

May 2000, Laser

Technology Follows in Lawrence’s Footsteps

-

September 2001, Lasershot

Makes Its Mark

-

November 2001, New

Targets for Inertial Fusion

-

April 2002, Bright

Future for Tactical Laser Weapons

-

May 2002, At

Livermore, Audacious Physics Has Thrived for 50 Years

-

June 2002, Adaptive

Optics Sharpen the View from Earth

-

September 2002 Empowering

Light - Historic Accomplishments in Laser Research

|

| FAIR USE NOTICE: This page contains copyrighted

material the use of which has not been specifically authorized by the copyright

owner. Pegasus Research Consortium distributes this material without profit

to those who have expressed a prior interest in receiving the included

information for research and educational purposes. We believe this constitutes

a fair use of any such copyrighted material as provided for in 17 U.S.C

§ 107. If you wish to use copyrighted material from this site for

purposes of your own that go beyond fair use, you must obtain permission

from the copyright owner. |

|

~ MENU ~

|