by

S. Gunnar Sandberg

(School of Engineering & Applied

Sciences, University of Sussex)

June 1985

The objective of this report is to

reconstruct the experimental work carried out between 1946 and 1956 by

John R. R. Searl that concerns the geometry, materials used, and the manufacturing

process of the Sear1-Effect Generator (SEG).

The information given here is based

on private communication between the author and Searl and should be considered

preliminary as further research and development may give reason to alter

and/or update the content.

The Gyro-Cell ~

The SEG consists of a basic drive

unit called the Gyro-Cell (GC) and, depending on the application, is either

fitted with coils for generation of electricity or with a shaft for transfer

of mechanical power. The GC can also be used as a high voltage source.

Another and important quality of the GC 1s its ability to levitate.

The GC can be considered as an electric

motor entirely consisting of permanent magnets in the shape of cylindrical

bars and annular rings.

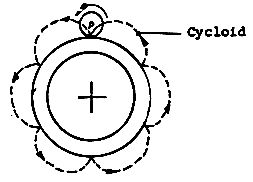

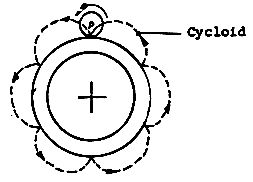

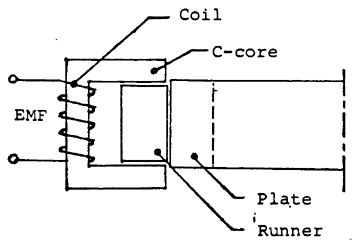

Figure 1 shows the basic GC in its

simplest form, consisting of one stationary annular ring-shaped magnet,

called the plate, and a number of moving cylinder-shaped rods called runners.

Figure 1 ~

During operation each runner is spinning

about its axis and is simultaneously orbiting the plate in such a manner

that a fixed point p on the curved runner surface traces out a whole number

of cycloids during one revolution round the plate, as shown by the dotted

lines in Figure 2.

Figure 2 ~

Measurements have revealed that an

electric potential difference is produced in the radial direction between

plate and runners; the plate being positively charged and the runners negatively

charged, as shown in Figure 1.

In principle, no mechanical constraints

are needed to keep the GC together since the runners are electromagnetically

coupled to the plate. However, used as a torque producing device, shaft

and casing must be fitted to transfer the power produced. Furthermore,

in applications where the generator is mounted inside a framework, the

runners should be made shorter than the height of the plate to prevent

the runners from catching the frame or other parts.

When in operation, gaps are created

by electromagnetic interaction and centrifugal forces preventing mechanical

and galvanic contact between plate and runners and thereby reducing the

friction to negligible values.

The experiments showed that the power

output increases as the number of runners increase and to achieve smooth

and even operation the ratio between external plate diameter Dp and runner

diameter Dr should be a positive integer greater than or equal to 12. Thus:

(1) P/Dr

= N > 12 (N = 12, 13, 14, &c)

The experiments also indicated that

the gaps O between adjacent runners should be one runner diameter D as

shown in Figure 1.

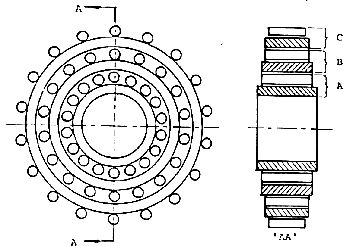

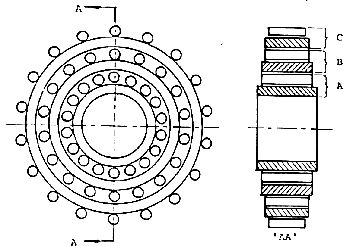

More complex Gyro-Cells can be formed

by adding further plates and runners to the basic unit. Figure 3 illustrates

a 3-plate GC consisting of three sections, A, B and C. Each section consists

of one plate with corresponding runners.

Figure 3 ~

The experiments showed that for stable

and smooth operation sections should be of equal weight. Thus:

(2) WA

= WB = WC

where

WA = weight of section

A,

WE = weight of section

E,

WC = weight of section

C.

The Magnetic Field Configuration

~

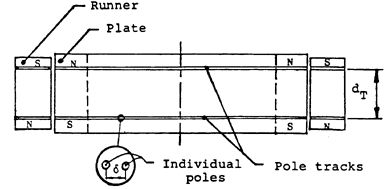

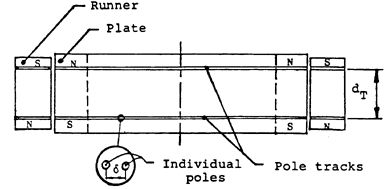

Due to a combined DC and AC magnetising

process, each magnet acquires a specific magnetic pole pattern recorded

on two tracks consisting of a number of individual N-poles and S-poles,

as illustrated in Figure 4.

Magnetic measurements have revealed

that the poles are approximately one millimetre across and evenly spaced.

It was also found that the pole density (x) --- defined as the total

number of poles N per track divided by the circumference, pi D --- must

be a constant factor specific for a particular generator. Thus:

x = Np / 3.14 Dp

=

Nr / 3.14 Dr

where Np is the total

number of poles per track on plate and N r is the total number

of poles per track on runner.

Figure 4 ~

Furthermore, the distance dr

between the two pole tracks must be the same for all runners and plates

which are parts of the same GC.

The pole tracks allow automatic commutation

to take place and create a turning moment. Exactly how this is achieved

is not understood and will require further research efforts.

Likewise, the source of energy is

at present unknown. Further research is also needed to establish the exact

mathematical relationship between output power, speed, geometry and material

parameters, such as mass density and electromagnetic properties of the

materials used.

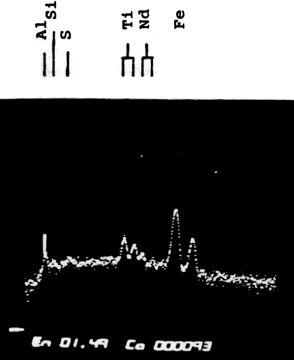

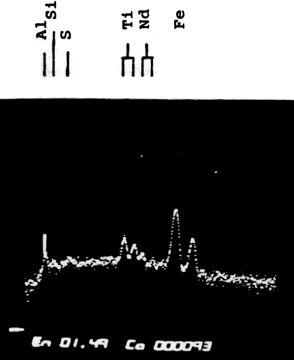

Magnetic Materials ~

The magnets used in the original

experiments were made of a mixture of two types of ferromagnetic powders

imported from the USA. One of these magnets, still in existence, has been

qualitatively analyzed and was found to contain the following elements:

Aluminum, Silicon, Sulfur, Titanium, Neodymium, Iron. The spectrogram is

illustrated in figure 5.

Figure 5 ~

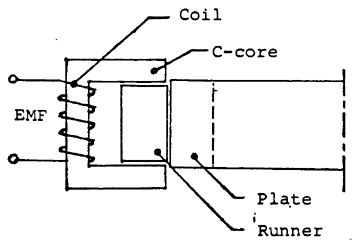

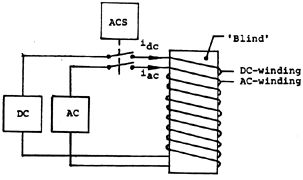

The Induction Coils ~

If the SEG is sued as an electrical

power plant a number of induction coils must be fitted to the GC. The coils

consist of C-shaped cores made of soft steel (Swedish steel) or high u-ferrite

(mu-metal). The number of turns and wire gauge used depends on the application.

Figure 6 shows the basic design.

Figure 6 ~

Manufacturing Procedure ~

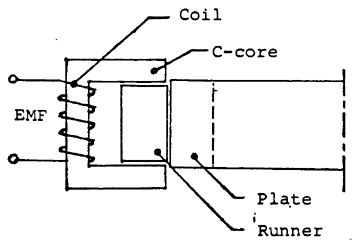

The block diagram in Figure 7 illustrates

the main stages in the manufacturing process.

Figure 7 ~

(1) Selection of Magnetic

Materials >> (2) Weighing >> (3) Mixing >>

(4) Moulding >> (5) Machining >>

(6) Inspection > (7) Magnetization >>

(8) Inspection >> (9) Assembly >>

(10) Final Control.

Stage 1: Magnetic Materials &

Bonding Agents ~

It is feasible that future research

will reveal other magnetic raw materials to be cheaper and/or more efficient

than the ones used in the original experiments. It is also possible that

other types of binder may improve the performance.

Stage 2: Weighing ~

In general, to produce efficient

magnets the right amount of each element contained in the ferromagnetic

powder is crucial. It is therefore reasonable to suggest that when mixing

different types of powders an optimal weight ratio does exist that will

produce a 'best' magnet.

At present, however, this weight

ratio is not known for the powders used by Searl in his past experiments.

Together with new magnetic materials and optimization of generator geometry,

this is an area in which research efforts could be profitable.

In general, the amount of binder

used should be as small as possible to achieve maximum mass density of

bonded magnets. However, the possibility that the binder is taking an active

part in the generation of the Searl-Effect must not be excluded. For instance,

the dielectric properties of the binder may play an active role in the

electromagnetic interactions taking place in the SEG. If that is the case,

then a further amount of bonding material may be beneficial.

Stage 3: Mixing ~

The mixing is an important process

which will decide the homogenity and reliability of the finished product.

A homogeneous mixture can be achieved by using turbulent air flow inside

the mixing container The experiments did show that an improved performance

was achieved if all magnets for the same generator were made from the same

batch.

Stage 4: Moulding ~

During the moulding process the compound-

consisting of ferromagnetic powders. and thermoplastic binder is compressed

and simultaneously cured by heating. Figure 8 illustrates the tool used

for making 'blinds'. A 'blind' is an unmagnetized runner or plate/part

of plate. When manufacturing large plates (Dp > 30 cm) it may

be necessary to make them in segments rather than in one piece.

Figure 8 ~

The figures given below should be

considered as guidelines only, since correct data are not available regarding

the influence of the moulding process on the Searl-Effect.

1. Pressure: 200-400 bars

2. Temperature: 150 C-200 C

3. Compression time: > 20 minutes.

Before releasing the pressure the

mould must be allowed to cool.

Stage 5: Machining ~

This process can be bypassed if the

weighing and moulding procedures are carried out correctly. However, it

may be necessary to polish the cylindrical surface of runners and plates.

Stage 6: Inspection ~

Control of dimensions and surface

finish.

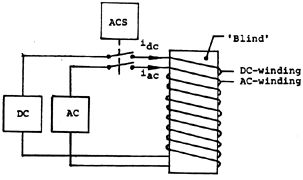

Stage 7: Magnetization ~

Runners and plates are individually

magnetized in a combined DC and AC-field during one on-off duty cycle.

Figure 9 illustrates the magnetizing circuit.

Figure 9

~

The function of the automatic control

switch (ACS) is to simultaneously switch on the DC-current, idc

and the AC current, iac at such a time, t = ton,

that the instantaneous value of the total magnetomotive force (MMF) is

always positive. Thus:

MMF = idcN1

+ iacN2 > 0

Where N1 is the number

of turns in the DC-winding and N2 is the number of turns in

the AC winding.

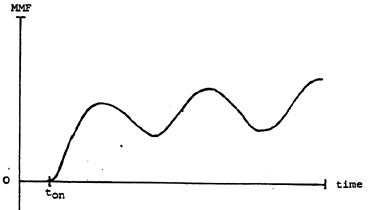

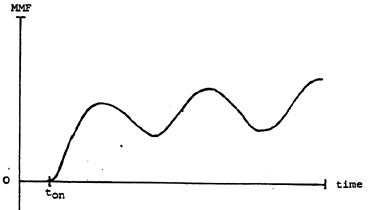

Figure 10 shows the total MMF as

a function of time.

Figure 10

~

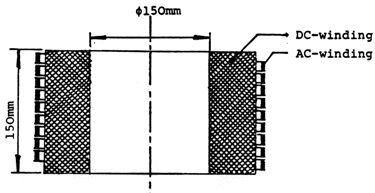

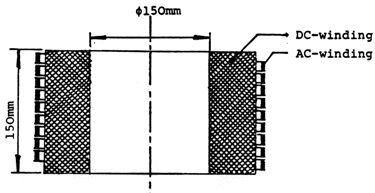

The magnetization coil consists of

a DC winding containing approximately 200 turns of heavy copper wire and

an AC winding containing approximately 10 turns of copper strip wound on

top of the DC winding. Figure 11 shows a cross-section of the coil and

its dimensions.

Figure 11 ~

Recommended parameter values:

DC current, idc = 150

A to 180 A

AC current,

iac = 0.1 to 0.2 A

Frequency,

f = 1-3 MHz

Stage 8: Inspection ~

The purpose of this control is to

test for the existence of and the correct spacing of the two pole tracks.

The measurements can be made with a magnetic flux density meter in combination

with a set of control magnets.

Stage 9: Assembling ~

The assembling procedure depends

on the application. Used as a mechanical drive unit, the magnets must be

mounted inside a framework and fitted to a drive shaft. Used as an electric

power plant, induction coils must be fitted to the framework.